Projects

Selected Engineering Projects

These projects reflect my interest in hands-on engineering, rapid iteration, and building practical tools.

Professional projects are described at a high level and avoid proprietary details.

Hardware-Accelerated Cryptography Integration

Problem:

Integrate and validate hardware cryptographic engines across multiple microcontroller families while maintaining a consistent API surface.

What I Worked On:

- Integrated AES (ECB, CTR, GCM, CCM, XTS), SHA, ECC, TRNG, and PKE hardware engines

- Designed wrapper layers to normalize behavior across different hardware implementations

- Debugged DMA interactions, interrupt behavior, and hardware state machines

Key Takeaways:

- Hardware acceleration introduces non-obvious timing and state constraints

- Clear abstraction boundaries are critical for long-term maintainability

Host-Side Embedded Test Framework

Problem:

Embedded cryptographic code is difficult to validate purely on-device.

What I Built:

- Host-side unit testing framework using CMake, Unity, and GCC

- Hardware abstraction mocks for crypto engines, DMA, and interrupts

- Automated regression testing and coverage reporting

Why It Matters:

- Enables fast iteration without flashing hardware

- Improves confidence in correctness and edge cases

Personal & Side Projects

These projects reflect my interest in hands-on engineering, rapid iteration, and building practical tools.

Mini Guitar Hero Controllers

Motivation:

Commercial Guitar Hero controllers have become surprisingly expensive, and I already owned a 3D printer along with many of the required electronic components.

Rather than purchasing new controllers, it was cheaper and more interesting to build my own.

What I Built:

- Compact custom Guitar Hero-style controllers

- Used an ATmega32U4-based board (Arduino Micro form factor) for native USB HID support

- Leveraged existing parts such as switches and wiring, minimizing new component costs

- Designed and 3D-printed the enclosure and mechanical components

Why It Was Worth Doing:

- Reduced cost compared to buying original controllers

- Full control over form factor and input layout

- Reinforced firmware, hardware, and mechanical integration skills

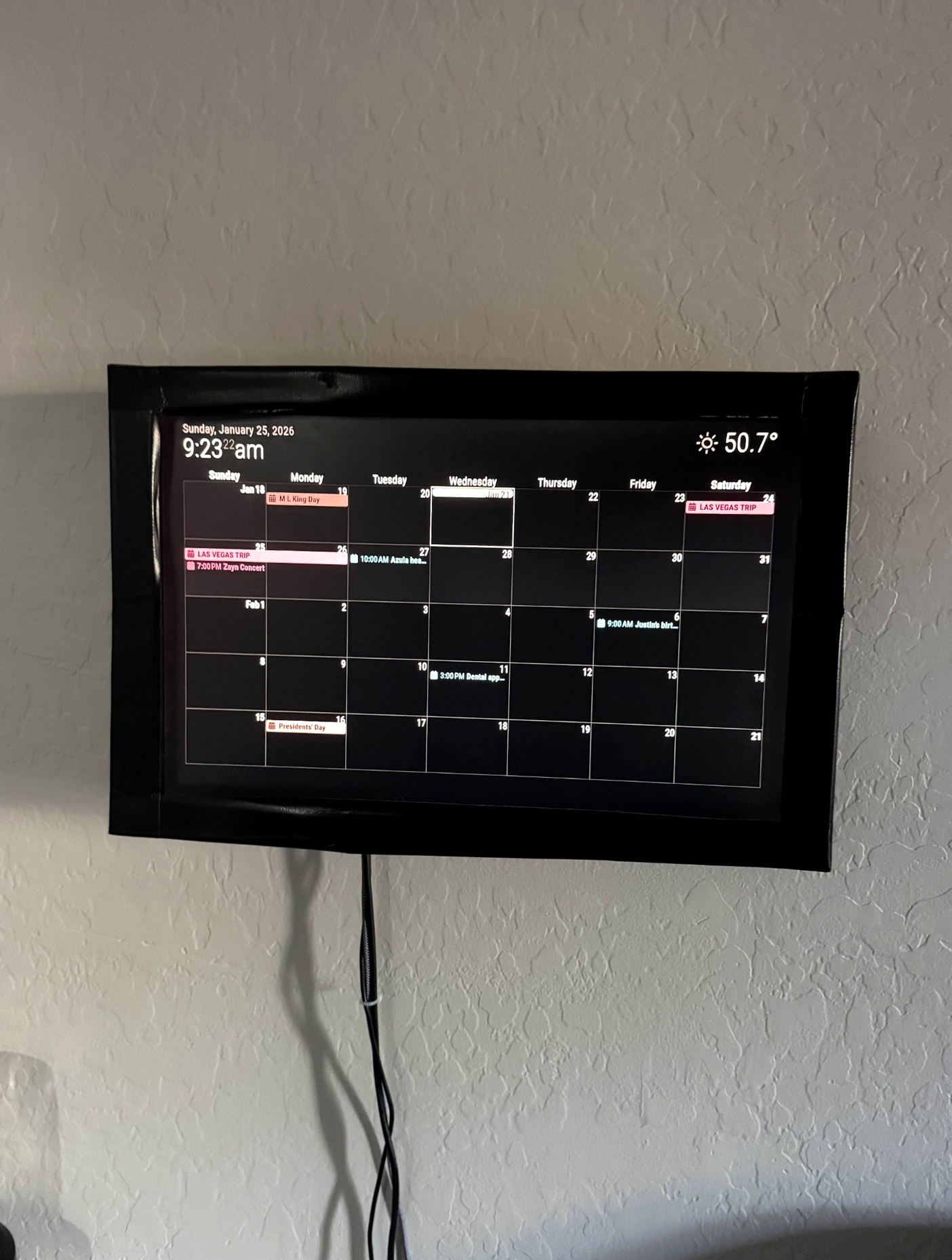

Shared Household Calendar (Magic Mirror–Style Display)

Motivation:

At one point, my girlfriend, her parents, and I were all living in the same house. Coordinating appointments, vacations, and medical visits across multiple people became difficult using individual calendars.

We needed a single, always-visible source of truth.

What I Built:

- A shared calendar display connected to multiple Google Calendar accounts

- Integrated each person’s calendar with color coding to clearly show:

- Who has events

- What day events occur

- Overlapping schedules

- Designed the system to be readable at a glance from across the room

Why It Was Worth Doing:

- Reduced scheduling conflicts and missed appointments

- Improved visibility for shared plans and travel

- Demonstrated practical integration of software services into a physical display

Shop Vac → Pet Vacuum Adapter

Motivation:

Pet grooming vacuum attachments are convenient but often limited by weak suction and small collection capacity. I already owned a shop vacuum with significantly stronger suction power and a much larger capacity.

The goal was to reduce grooming time and avoid frequent stops to empty the vacuum by leveraging equipment I already had.

What I Built:

- A custom-designed adapter to connect pet grooming vacuum brushes to a shop vac

- Iterated the adapter design using 3D printing to ensure proper fitment and airflow

- Designed the part to be durable enough for repeated use while maintaining a good seal

Why It Was Worth Doing:

- Stronger suction improved grooming effectiveness

- Larger capacity reduced interruptions during grooming sessions

- Less time wasted grooming

- Reinforced practical mechanical design and rapid iteration skills

3D Printing & Functional Parts

- Design and print small functional components, adapters, and fixtures

- Focus on tolerances, mechanical fit, and real-world usability

- Frequently used to support electronics, prototyping, and household projects